Over 26 Years Of Experience In The Auto Parts Industry

DIESEL ENGINE & TRANSMISSION

SPARE PARTS

SUPPLIED BYVOLGENPOWER since 1998

Professional Supplier for Diesel Engines, Crankshafts, Transmission Gearbox, Axle, and Spare parts. In a single group, the world’s quality guarantee of spare parts for the aftermarket.

CUMMINS DIESEL ENGINE PARTS

Volvo gearbox&Spare parts

As a trusted provider of Volvo gearbox parts in China, we offer an extensive range of high-quality components, including manual and I-Shift models like the VT2514B and AT2612D. Our products leverage advanced technology, ensuring top-tier quality, long-lasting durability, and enhanced fuel efficiency for smooth gear shifting. Supported by expert technical guidance, prompt customer service, and a two-year warranty, we keep your fleet performing at its best. Partner with us for tailored, budget-friendly solutions and access to premium Volvo transmission parts.

Product Series

As a leading diesel engine supplier and dealer, we specialize in commercial vehicle engine parts, ensuring you have access to top-quality diesel engine parts.

More detail models

In our range you could find all kinds of engine parts that are high quality and premium branded for trucks, buses,construction machinery, marine propulsion and auxiliary engines, generator sets.

Our range includes spare parts for many brand engine,such as Dongfeng LONNG-GINE engine,Cummins engine,Perkins engine,Caterpillar engine,Wechai engine,Yuchai Engine,Shangchai Engine and other China brand engine.

We export the largest range of high quality and genuine branded diesel engine parts for your engine rebuilding needs. We most struggle for great customer support and we have the experience to get you the parts which you need at the best prices.

More detail models

In our range you could find all kinds of transmission gearbox assembly and spare parts that are high quality and premium branded fortrucks, buses.

Our company is the franchised dealer of Dongfeng Commercial Vehicle Powertrain Division,can provide Lonng-Gine Series transmission DA14 automatic transmission and DT14 manual transmission.We also provide full series of FAST brand transmission assembly and spare parts, includes medium heavy truck transmissions 8JS,9JS,10JS,12JS,16JS series;Bus transmissions 5J,6J,5DS,6DS series and AMT transmissions 10-16JZSD series.

More detail models

In our range you could findhigh quality and premium branded axle assembly and spare parts.

Our range includes Dongfeng DANA axle and Shanxi Hande axle,used for Trucks,Buses,Construction,Material Handing,Underground Mining,Agriculture and other application.

100%

High QUALITY

DIESEL ENGINE PARTS

Everywhere Our Customers Are

Together, our global presence and robust delivery capabilities allow us to efficiently meet region-specific production needs, anywhere in the world.

Global Customers

World-renowned Brands

Countries

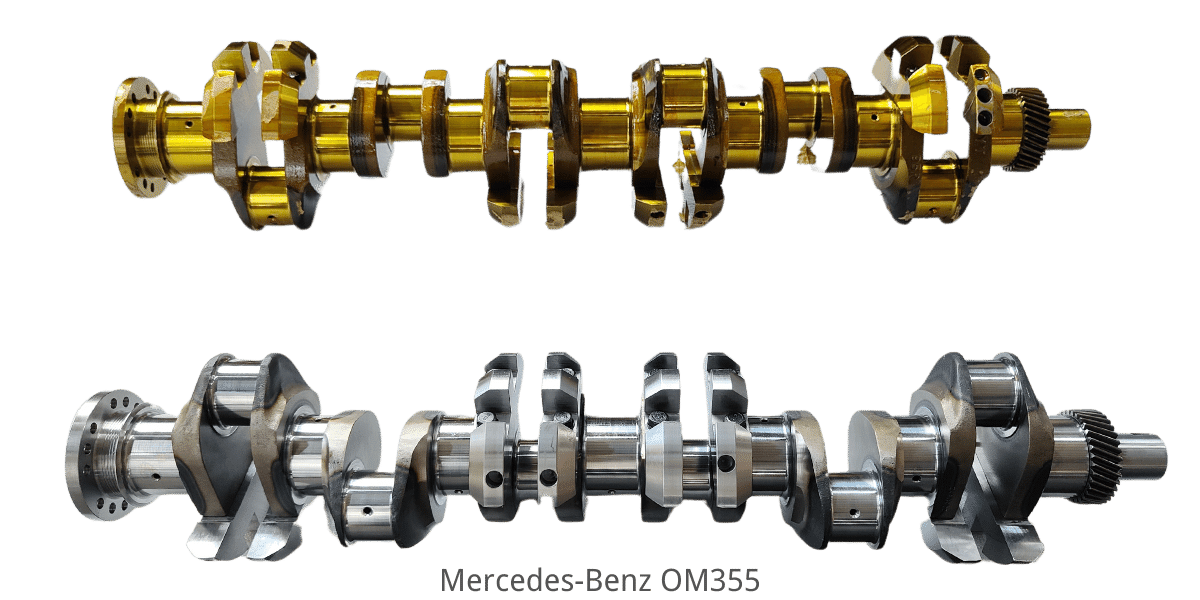

Crankshaft Factory

Our crankshaft factory features advanced capabilities with two flexible automatic production lines that produce over 60000 crankshafts annually.

We cater to a diverse range of engines, manufacturing crankshafts for 4, 6, 8, and 12 cylinder engines, with lengths varying from 450mm to 1500mm.

- Cummins 4BT, 6BT, 6CT, ISF, ISB, ISD, ISC, ISL, M11, NT855 series,

- Lovol, Mercedes Benz OM457, OM906, OM904 series, Volvo FH12, and MAN 7, 11, 13 series

OEM CUSTOMIZED

Leveraging two decades of industry expertise and state-of-the-art machinery, our facilities are equipped to manufacture a comprehensive range of components from bespoke designs. We specialize in bevel gears, gears, transmission shafts, and synchronization shafts tailored for any assembly line. Additionally, we offer exclusive, custom-built solutions to meet diverse production requirements.

TRUST

Trust us to deliver not just auto parts, but peace of mind with each crankshaft—meticulously crafted to meet stringent quality standards at prices that make sense for your business.

QUALITY

Committed to excellence, our crankshafts undergo rigorous testing to ensure unmatched quality and reliability, so you can drive your business forward with confidence.

Trustworthy Supplier

“As a buyer, I confirm that VOLGENPOWER has found the perfect balance between price and quality. Over the past year, our procurement costs have decreased by 15%, while their parts have maintained a failure rate of less than 0.5%. This meets our budget requirements and ensures long-term high quality. VOLGENPOWER is a trusted partner in our supply chain.”

“Since switching to VOLGENPOWER, our defect rates have dropped from 2% to 0.3%. This remarkable improvement has saved us over $20,000 in rework and warranty costs annually.”

“VOLGENPOWER’s customer service is exceptional. Any issues we’ve encountered have been resolved within 24 hours, and their technical support team has provided invaluable assistance, contributing to a 15% increase in our operational efficiency.”

“Our partnership with VOLGENPOWER has been instrumental in reducing our inventory holding costs by 10%. Their reliable supply chain management ensures that we have the right parts at the right time, every time.”

Choose Us Choose A Team

Since 2001, Volgenpower has been a beacon of excellence in automotive components. With 20+ years of expertise, we’ve earned a global reputation across 70+ countries, offering tailored premium solutions that meet diverse market demands. Our extensive range, from diesel engines to gearboxes and spare parts, is backed by a commitment to customer satisfaction, ensuring exceptional service at every turn. Choose us for a partner dedicated to your success, with reliability and a service-driven approach at our core.

Get In Touch

Location

No.18.Hexie Avenue.Shiyan City,Hubei Province,China